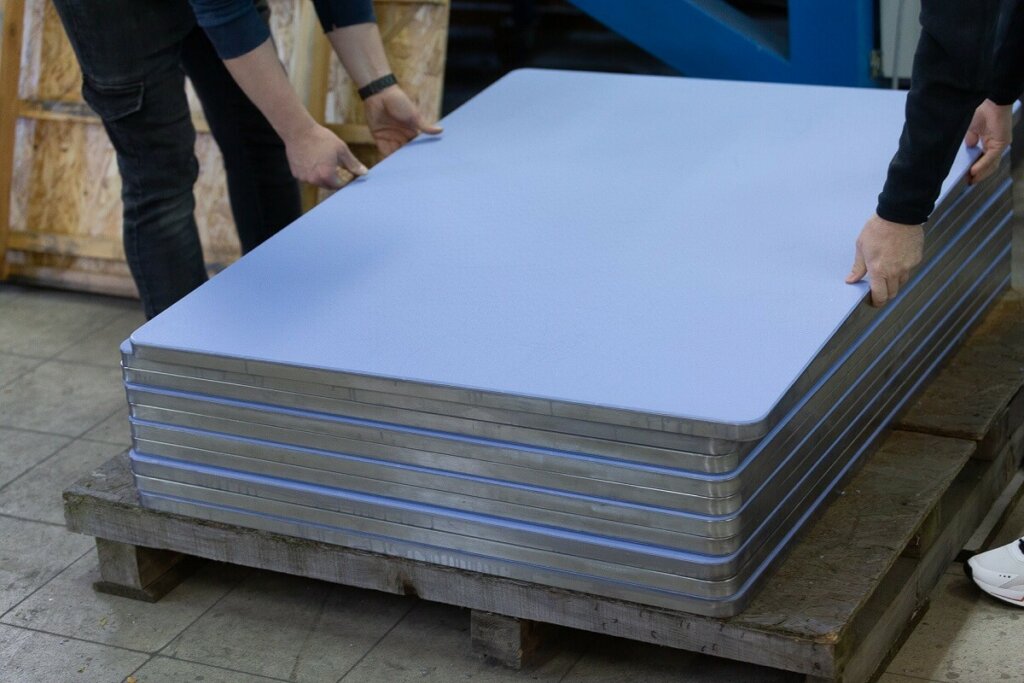

Quality, hygiene and ergonomics – the proofing peelboard

Proofing products are essential equipment for every plant. We know perfectly well that their quality must be at the highest level. To meet the expectations of the bakery industry, we have developed a solution that will help to carry out this process without additional complications. Our proofing peelboard was designed for automatic and industrial lines, as well as for craft production. We have used solutions that guarantee better hygiene and ergonomics requirements during production. See the advantages of the honeycomb structure and why it is the peelboard that we devoted to one of our newest, comprehensively equipped production halls.

See how we grow → Magorex bakery equipment: new production halls and products

Peelboard for proofing – get to know it better

Why is wooden proofing boards’ popularity constantly declining? Even if we may encounter many other technical problems along the way, hygiene is the issue of the night. The exceptional temperature and humidity that prevails during this arduous process favour the formation of mould and fungus. That’s why you can find more and more accessories of this type made of synthetic materials. The most popular among them is the special Magorex proofing peelboard.

We wanted our peelboard to be even easier to use and enable a more economical baking automation system. The result of efforts is a universal tool suitable for all types of baking. It is possible to plan and improve productivity in a nearly unlimited way. What else speaks in favour of a proofing peelboard? The option of comprehensive automation, increasing efficiency and a steady, fast pace of work. It, however, does not take place at the expense of the unique qualities of the final product.

See what our peelboard was made of and what other possibilities it has → Easier proofing of dough with a peelboard from Magorex

Proofing peelboard – what is its advantage?

It is the customer who decides on the details of the product. Our peelboard is available in any dimension and with three variants of corners to choose from: rounded (30 degrees), square (90 degrees) or cut (45 degrees). Are you curious about its other advantages? See what our sales advisor, Jakub Panek, has to say about the peelboard:

Peelboard for proofing – how is it built?

Of course, all this would be impossible if it were not for the well-thought-out design and carefully selected materials. The outer surface of the peelboard is made of ABS synthetic material, which is particularly resistant to deformation, scratching and impacts, the action of various substances, and chemical factors. Even under the influence of washing in dishwashers, the use of cleaning agents or exposure to certain temperatures, the peelboard does not deform and is immediately ready for further use. Its diversified structure also deserves special attention. On the one hand, it has a surface ideal for products sprinkled with flour, and on the other – a special, air-permeable coating, thanks to which the dough will not stick.

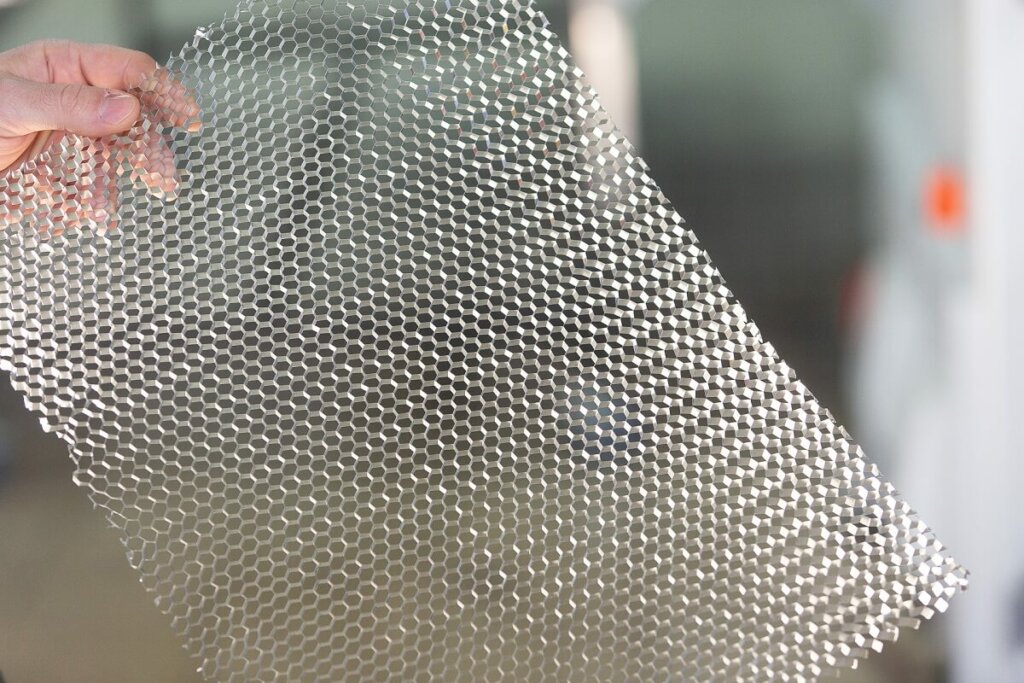

It is no coincidence that the board remains perfectly stiff and flat all the time. We could achieve this result thanks to the welded, aluminium frame, and a tight, internal mesh with an innovative honeycomb structure. The history of this solution dates back to the beginning of the 20th century. It is now used in many industries and has become part of a wide range of products. Why did we choose it, and what are the benefits?

Aluminium honeycomb structure

- less material used

- lower costs

- unique properties

The honeycomb structure owes its name to a hexagonal system, inspired by the honeycomb produced by bees.

Used wherever light, durable and flat surfaces are needed, this filling has also taken the baking industry by storm. Depending on what effects we want to achieve, we can use many different materials for production. We chose aluminium, a material with many years of durability, resistance to corrosion and high temperatures. Thanks to this, the project of the peelboard for proofing turned out to be such a great success.

Find out more about the advantages of aluminium for the baking and confectionery industry →

Advantages of the honeycomb structure

Although the appearance of the honeycomb structures may differ slightly, they all have a common feature of a series of hollow hexagonal cells arranged between thin walls. The presence of two coatings applied to this type of filling makes the final product perfectly stiff, mobile and even more durable. At the same time, it is very light, resistant to squeezing or crushing, energy-efficient and maximally ergonomic. But it is not everything. Its advantage is the low production costs, especially concerning the long service life of the accessories created in this way. Importantly, thanks to aluminium, honeycomb is recyclable and is environmentally friendly.