First of all, remember – in order to keep your sheets and forms in the best condition, when working with non-stick coatings, the way you use them is important. That is why we advise you to thoroughly train people who will work with your baking or confectionery equipment.

If you are the owner of sheets or moulds with anti-adhesive coatings, i.e. non-stick, also known as Teflon or Non-Stick, we have really good news for you – we can regenerate them for you. If, however, you are thinking about buying them, apart from the advantage of being able to regenerate them, they are simply coatings for special tasks. Thanks to them, the problem of growing kitchen waste, increasing costs of greasing products and the struggle with removing the bread from the mould are eliminated.

Coincidence breeds inventions

Revolutionary inventions often came about by chance. It was the same with non-stick coatings. In 1938, the American chemist Roy Plunkett, while working on cooling agents, discovered that the material he created was extremely heat and chemical resistant. 20 years later, Teflon, as he called it, was appreciated by many industries, including food. Why? The secret lies in the properties of the material.

Advantages of anti-adhesive, i.e. non-stick coatings:

- Thermal resistance – both to high and low temperatures, as well as UV radiation and chemical agents,

- Non-stick and anti-corrosion, thanks to which production efficiency increases and costs decrease, because there is no need to use greasing agents, and we gain time and save costs spent on cleaning and care,

- Physiological inertness, thanks to which this material is approved for contact with food – Magorex always has coatings of documented origin,

- Low coefficient of friction, thanks to which the dough does not stick and does not stratify immediately after removal,

- They help to obtain baked goods of consistently excellent quality; the dough rises better and the crust forms at the right rate, browns evenly and stays crunchy.

- The possibility of regeneration, i.e. removal and application of a completely new coating, thanks to which we reduce operating costs.

Find out more about materials from which the Magorex assortment is made →

Recoating, i.e. regeneration of Teflon

Your sheets and moulds have lost their original “glow”? Would you like to replace them with new ones, but this is not the best time for large investments? It’s definitely time to look at remanufacturing options.

The regeneration treatment consists of mechanical or thermal removal of the used coating. If necessary, we also make minor repairs. At the end of the process, we apply a completely new coating, thanks to which your equipment will regain excellent condition, which our customers even call the “wow effect” because the product looks like new. Best of all, we can repeat this process, even several times.

The cost of regeneration is 30% to a maximum of 40% of the new product.

At the customer’s request, we can additionally cover the moulds with black paint, which shortens the baking time by 8%, and additionally causes the effect of even baking. Are you worried that damaged equipment is only suitable for throwing away? Unnecessarily! Ask our experts.

Types of non-stick coatings

We offer several types of non-stick surfaces for sheets and moulds. Each of them is available on special order.

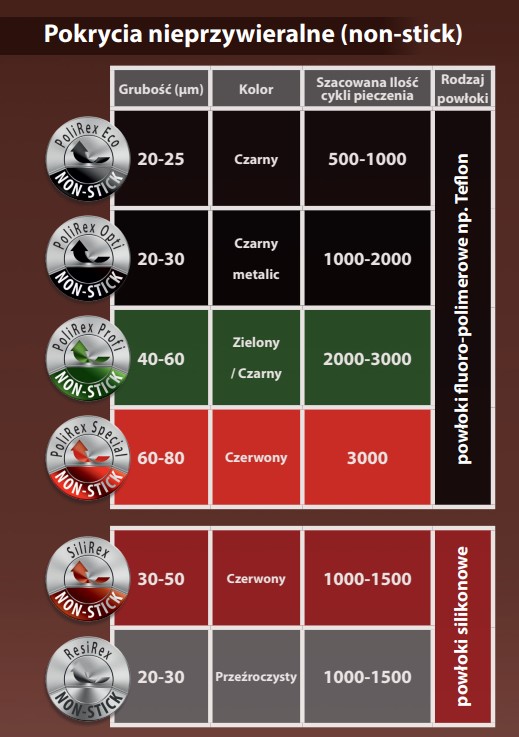

You can choose a silicone coating:

- SiliRex – 30-50 µm thick, red, the estimated number of baking cycles is 1000-1500,

- ResiRex – 20-30 µm thick, transparent, 1000-1500 baking cycles.

The silicone coating works best up to 1500 baking cycles. Importantly, it is the most suitable for working with products with a high content of sugar and protein.

You can also choose fluoropolymer, i.e. Teflon, coatings that we regenerate:

- PoliRex Eco – has a thickness of 20-25 µm, is available in black, and its estimated number of baking cycles is 500-1000;

- PoliRex Opti – thickness 20-30 µm, black metallic, estimated number of baking cycles is 1000-2000;

- PoliRex Profi – has a thickness of 40-60 µm, is available in green or black, the estimated number of baking cycles is 2000-3000;

- PoliRex Special – has a thickness of 60-80 µm, is available in red, and its estimated number of baking cycles is 3000.

Teflon coatings have a longer life, depending on the selected type, they retain their properties for 500 to 3000 baking cycles. In addition, at Magorex, we offer the possibility of reclamation of their coatings, which significantly reduces the operating costs of your business.

Back to basics - golden rules of use

What can be done so that the sheets do not lose their properties quickly? We remind you of a few basic rules that will help you make the most of their potential and influence their longest possible life:

- Do not cut over coatings or use sharp tools – be careful with pry blades, knives, scrapers and other utensils that can damage the surface.

- Do not bake the sheet or forms without a load – this significantly reduces the life of the coatings.

- Store carefully – so as not to damage the coating.

- Ensure constant air humidity in the proofer – this will keep the coatings in good condition.

- Dry and cool the moulds before use – otherwise, the dough will stick and damage the coating. It is best to dry the moulds upside down and let them dry naturally.

Remember that the number of baking cycles for non-stick surfaces also depends on what you bake in them.

And how to clean them to keep their full properties? The simple 3-step method works best.

3-step cleaning of accessories with non-stick coating

- Gently wipe the soiled areas with a soft sponge and warm water.

- Shake water off the sheet or mould.

- Air dry or in an open oven for 15-20 minutes at 150 °C.

Are you looking for other solutions that will help you fight carbon deposits? Not all of your trays and moulds have a non-stick coating? To solve this problem, we have created a dedicated HAEM cleaning liquid (for sheets and forms) or gel (for baking trolleys).

Long live our trays and moulds!

The valuable properties of non-stick coatings have a certain lifespan. The warning sign is when the dough starts to stick to them. However, the wear process can be delayed by careful cleaning and treatment, i.e. proper work culture. However, remember about the regeneration option, which significantly reduces costs, and thanks to it your sheets or moulds can gain a second or even a third life.