Automation of baking bread – what are its advantages?

Representatives of the baking industry are still facing the problem of a shortage of employees for their needs. Investments in modern systems and technological solutions are more and more often a solution that will help them maintain high efficiency and production efficiency. Automatic lines and modern bakery equipment effectively replace the staff, reduce the need for manual work and allow to bake high-quality bread with a constant, fast pace of work.

The possibility of achieving much greater efficiency and the repeatable quality of the assortment are basic arguments that appeal today to the owners of large industrial plants and medium-sized artisan bakeries. Automation of loading dough requires the most ergonomic devices and accessories. Which peelboard for the automatic loading system is the best?

Automatic loading system – innovative solutions for bakeries

Until recently, the serving and laying of bread required the active participation of employees. However, manual billet transfer takes much longer and is not without significance for the final baking quality. Nowadays, an automatic system offers the possibility of free production planning and limiting the human factor at every stage of loading and unloading. How is it done?

Today, the best solution for placing dough on a rack in a proofing and cooling room is a peelboard. It has an advantage over conventional loading apparatuses, e.g. in terms of ergonomics. It can be used during proofing, freezing and transporting any product.

Efficiency, quality, ergonomics

At a convenient time, the automatic system takes over the fermentation trays and transports them under the production belt, which collects and transfers the dough to the loading table. Everything is done quickly, efficiently and without damaging its delicate structure. To achieve the expected results, however, you must first look for reliable devices and accessories that optimally suit the plant’s needs. It turns out that it is necessary to select not only the entire feeding system but also additional elements, such as a peelboard for proofing.

Check where we are working on our product range → Magorex bakery equipment: new production halls and products

Which peelboard for the automatic loading system is the best?

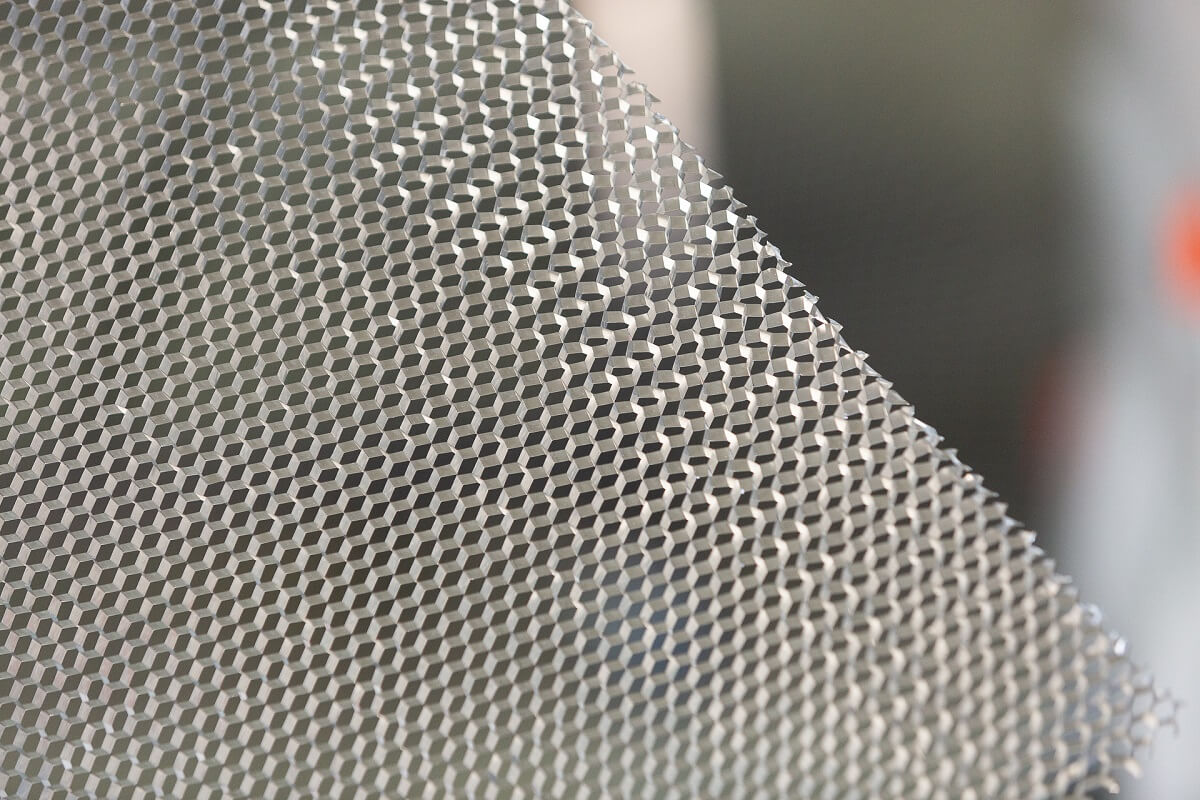

Peelboards used during this process should have the appropriate dimensions determined during individual talks with clients. The shape of the corners is also noteworthy. Some plants work best with rounded corners (30 degrees), while others – square (90 degrees) or truncated (45 degrees). What else matters? Firstly, ergonomics and durability. The double-sided outer surface of our peelboards is a 2 mm thick ABS synthetic material. While one side of the tray is for floured products, the other flank has an optimally roughened structure to prevent the dough from sticking. The welded profile and the internal aluminium honeycomb structure are responsible for high-pressure resistance, perfect stiffness and flat shape.

Ergonomic bakery equipment is an investment for the future. To serve us for many years, it should be made of durable materials. Production of peelboards for proofing takes place from scratch in one of our dedicated halls. It means that on request, we can prepare peelboards in even the most non-standard sizes that perfectly match the automated production line.

Do you want to know more about them? Check what solutions we used in his project → Peelboard for proofing – advantages of the honeycomb structure.