We focus on innovation

We focus primarily on intensive development and investing in advanced technological solutions. Since we make all the bakery equipment ourselves, we have been looking for a long time for tools that will help us increase the precision and efficiency of our work. Fortunately, the efforts paid off. Modern machines, which we purchased for each of our three production plants in recent years, have allowed us to successfully cooperate with the most important representatives of the bakery and confectionery industry. What innovations in the production of bakery equipment at Magorex have we introduced? How are we working now?

New Magorex production plants

Production automation, modern infrastructure and self-sufficient machine parks will allow us to perform individual orders for large industrial plants. We already established a clear direction of development almost ten years ago. Investment in new machinery and technology has brought excellent results, and today we can produce faster and better all the equipment our customers may need.

The construction of new production works turned out to be a natural step in our development. As the demand for our flagship products continues to grow, we wanted to devote them exclusively to the design and execution of orders for baking moulds and fermentation trays. This year we established the plant where we focus on the peelboards for proofing. We also maintain a modern Mould Pressing Center, where more than twenty supervise the production process.

Production of bakery equipment in Magorex

The employment of even more employees and the construction of new production halls would not mean so much if it were not for the advanced machinery to which we introduce new solutions. To ensure the safety and comfort of all teams while maintaining the highest production standards, we have equipped our plants with the most popular technology on the market.

These acquisitions include the Amada HFE 130-3L CNC press brake and the Baykal APHS 31120 press brake. We chose them for a reason. We wanted not only a much more convenient operation but also a reliable operation, regardless of the type and thickness of the material. Today, the precise bending effect is achieved in a shorter time and with less effort on the part of employees.

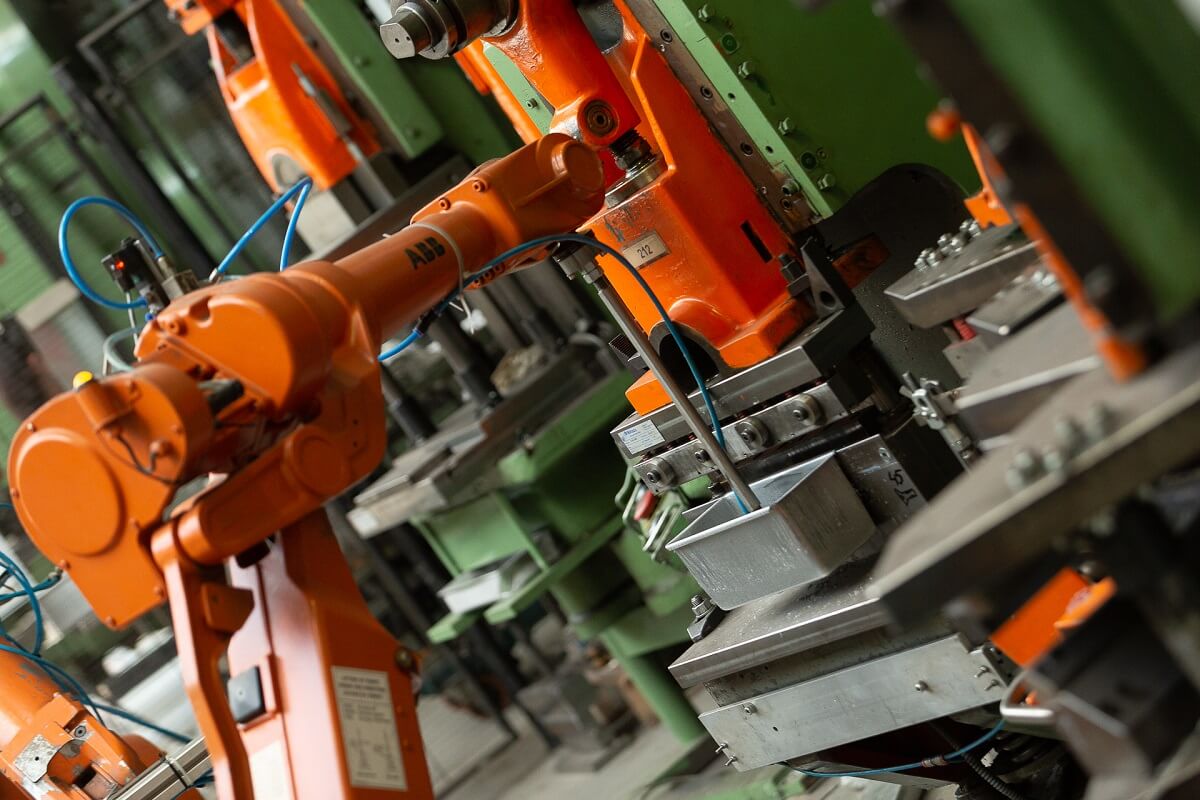

The gantry robot

We installed a modern gantry robot two years ago. It remains one of our most important investments. The machine is maintenance-free and requires only a little service with intensive use. It can effortlessly work all day with a minimal operator’s input, which is usually only needed for two activities: replenishing the mats and putting them away.

We notice the most significant difference in the case of serial production. The robot can perform bends based on designs and drawings of the specific type and size of the sheet. The work is continuous, repetitive and takes place in the same rhythm. When we use a press brake for manual bending, the robot drives aside until it is needed again.

Find out more about our gantry robot → Bakery equipment – on what machines is it made?

TRUMPF punch presses

Improving performance has been our priority for a long time. We knew that we had to invest in much more modern solutions for the production of the bakery equipment even when we were using old stamping presses. The answer turned out to be the revolver punching machines of the prestigious TRUMPF brand. The TruPunch5000 has allowed us to achieve new productivity standards, e.g. punching sufficient holes. Today, we can punch even 60 holes of any diameter during one stroke. The smallest ones are only 1.8 mm in size. The investment also turned out to be significant for our team, which can achieve satisfactory results in comfortable and safe conditions.