Aluminum or AluSteel?

The basic material used in many industries, including baking, confectionery and food production, has long been aluminium. Its popularity is due to its unique physical characteristics, such as low weight, corrosion resistance, excellent thermal conductivity, flexibility, and plasticity that allow convenient, creative processing. At the same time, the ecological benefits cannot be overlooked. Even if we recycle it many times, we will not have to worry about large losses of the raw material or a decrease in its class and properties.

Baking tests commissioned by us proved that aluminium moulds heat up much faster than steel moulds and retain heat better. Unfortunately, they can also be easily damaged mechanically. Slightly shorter service life and low impact resistance increasingly force industry representatives to look for new, reliable solutions. The answer to these worries turned out to be, among others, aluminized steel. What is this? What advantages does it have?

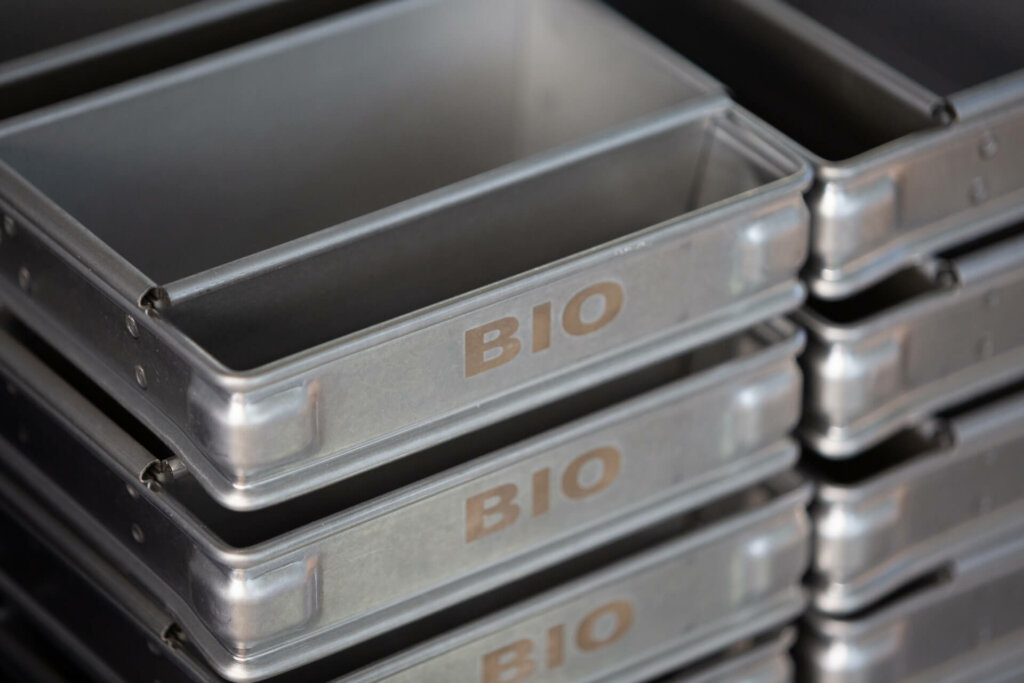

Aluminized steel moulds and sheets from Magorex

In all our projects, we focus on materials that will guarantee good performance, be durable and bring savings to future users. Stable, even baking bread on the sides and bottom is possible thanks to, among other things, traditional aluminium forms. In practice, however, they have several weaknesses that forced us to do further research and experimentation.

The result of these efforts turned out to be a series of products called AluSteel, i.e. carbon steel coated on both sides with a thin layer of aluminium. This construction provides even better protection against corrosion and the adverse effects of high temperatures. Aluminized steel is therefore much more durable, comfortable to use and resistant to deformation or mechanical damage. It also performs better in conditions of constant heating and cooling.

Advantages of AluSteel for the bakery and confectionery industry

The assortment used to bake aromatic buns, traditional bread, and sweet confectionery products must be ideally suited to the expected conditions of use. The most important thing is that the material is durable, safe in contact with food and easy to clean. At the same time, it should guarantee effective protection against the harmful effects of cleaning chemicals, water and other elements that are encountered every day in the production environment. All these benefits are brought today by sheets and forms that combine the unique properties of aluminium and carbon steel. What does it mean in practice? What are the advantages of AluSteel for the bakery and confectionery industry?

Durability and corrosion protection

Accidentally scratching the surface of sheets and moulds can be fatal. Inferior quality products in contact with moisture will gradually lose their properties. They will no longer be protected against rusting or chemical attacks. We took these problems into account already at the first stage of work. As a result, we were able to introduce accessories to the catalogue that are much more durable than classic aluminium. Even if their coating is damaged, the active ingredients of AluSteel will automatically create a passive, protective anti-corrosion layer. Unlike traditional solutions, aluminized steel will not start to deform as a result of high, variable temperatures.

Ergonomics and savings

In modern plants, it is more important than ever to minimize losses and look for savings. No wonder more and more bakers and confectioners invest in equipment and accessories that allow for long, efficient and energy-efficient use. The advantages of AluSteel are unquestionable in this case. This material allows you to shorten the heating time of the oven and optimize the baking process. Thus, we will be able to reduce energy consumption costs. At the same time, we will take care of the better quality and colour of the bread. How it’s possible?

Uniform colour, high quality of bread. AluSteel in baking tests

We don’t like to mince words. To find out which material has the best impact on the production processes and their effects, we commissioned baking tests. We delivered baking moulds from our offer to the Bakery Institute in the Netherlands – in the standard version and with external black painting. The results confirmed what we had long suspected. Aluminized steel moulds, especially if they are painted with special paint, are much more ergonomic and efficient, and at the same time bring the best results. Especially if their top layer is painted with special paint. The toasted bread obtained in the tests was of high quality, and the baking time was shorter and more even. The crust each time turned out to be crispy and had the right uniform colour. These results could not be repeated, among others, in acid-resistant stainless steel moulds.