Plant cleanliness key to delicious baked goods

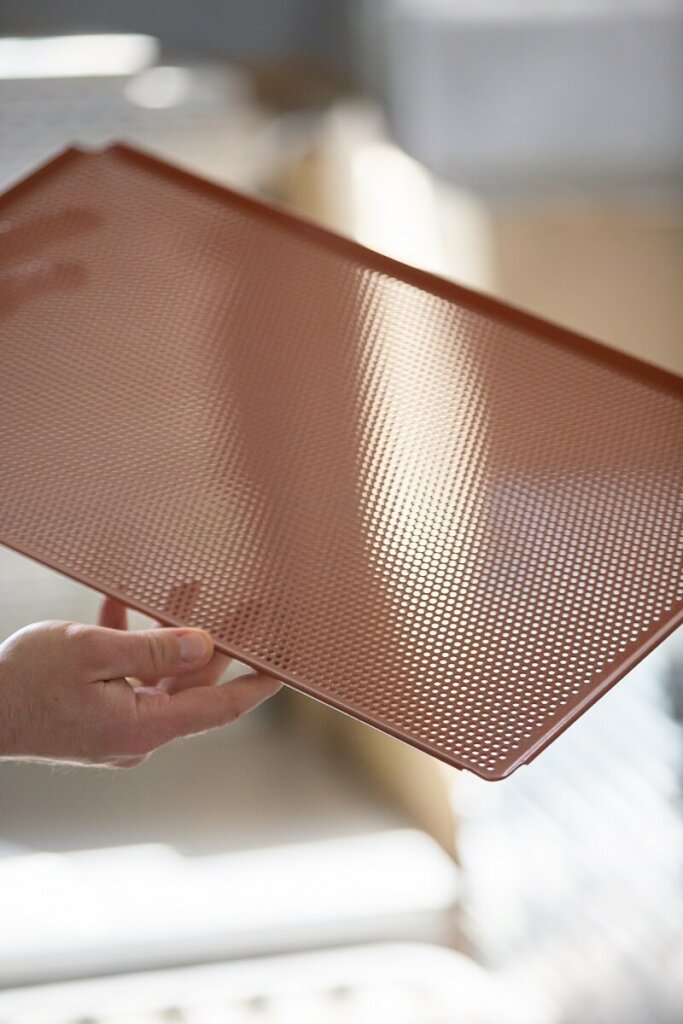

In addition, insufficient cleaning of bakery equipment can lead to malfunctioning equipment. The accumulation of dirt and debris on baking trays and moulds can lead to uneven heat distribution, which can result in uneven baking of baked goods. In addition, clogged holes and heat exchangers can reduce the efficiency of the equipment, leading to energy loss and compromised production results.

You want to know how to deal with these problems efficiently. Check out our three solutions!

Universal sheet cleaning machine

Say goodbye to manual cleaning of your equipment – the universal countertop sheet cleaning machine takes the work out of your employees. It is extremely popular with our customers and easy to use. The machine is ideal for removing traces of flour, grains and small dough residues after baking. Developed for continuous operation, it can clean up to 200 trays per hour, which will increase the efficiency of your establishment.

In addition, the machine takes up minimal countertop space, which is important in the planned space of a bakery or pastry shop. Thanks to its efficiency and effectiveness, the universal sheet cleaning machine is an essential piece of equipment in any bakery or confectionery production facility.

HAEM cleaning liquid

HAEM is an effective and efficient cleaning liquid, ideal for modern bakeries and confectioneries. The liquid is popular for its effectiveness, making production run more efficiently and reducing production costs. The liquid is safe for sheet metal surfaces and is suitable for use on steel, stainless steel and aluminium. An additional advantage is that it is reusable – simply filter out the residue that has accumulated after several cleanings. Importantly, HAEM is biodegradable, which is important for environmentally conscious manufacturers.

Burn-in of sheets and moulds before first use

Firing the baking trays before first use will ensure optimum preparation. In the case of Non-Stick coated baking trays, this involves baking the trays in an oven for approximately 45-60 minutes at 80-100 degrees Celsius. Once heated, the working surface of the baking trays should be coated with a layer of vegetable oil and then allowed to cool naturally at ambient temperature. If the sheets are silicone-coated, they should be subjected to a special baking process in an oven at 250 degrees Celsius for 60 minutes or 200 degrees Celsius for 4 hours. On the other hand, sheets coated with Polirex Green and Polirex Black coatings do not require a baking process before first use.

We offer a wide range of solutions and specialist products to help keep your bakery perfectly clean. Contact us if any of the products have piqued your interest.