Modern production line for sandwiches and ready meals

A modern, individually selected infrastructure guarantees an increase in efficiency, improves staff operations and enables production on an industrial scale. Those factors are necessary in the case of an extensive, demanding network of recipients. Improving efficiency, constant pace of technological processes and reducing losses are the goals that guided us while working on the last product. Thanks to the commitment, expertise and experienced specialists, we created the production line for sandwiches, salads, and ready meals. What are the fruits of their labour? When is it worth choosing such a solution?

Production line for salads and sandwiches – what are its advantages?

We don’t like to mince words. That is why we checked the functionality, ergonomics and reliability of our first automatic production line in tests first. The results exceeded our wildest expectations, and today we decided to introduce this product to our permanent offer. What benefits does it bring? Firstly, it allows you to perform even the most strenuous operations, such as portioning, adding ingredients and packaging, much faster and without additional burden for employees. What does this mean in practice?

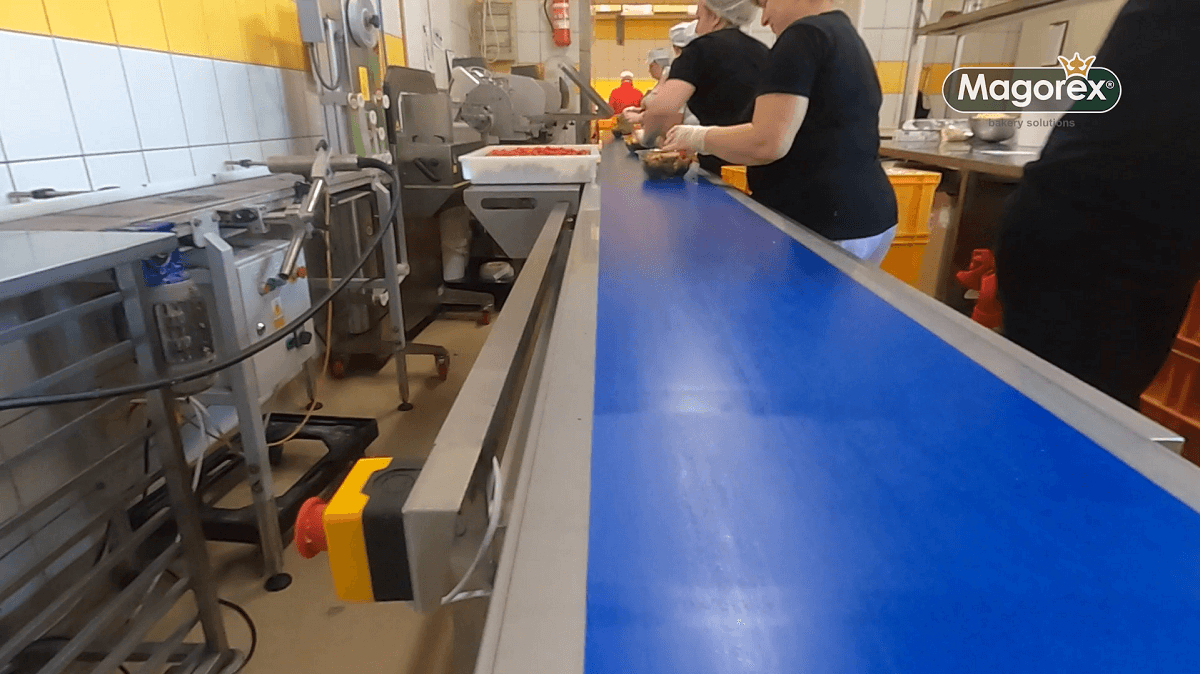

Lines for the production of salads and sandwiches consist of several interconnected stations. They are arranged in the correct, logical order. All this can work on your assortment in a harmonious and trouble-free way. Mixing raw materials and preparing ready-made dishes turns out to be much easier then, and there are no unpleasant surprises. Automatic production lines are a good idea whenever we want to take control of processes and avoid costly losses, mistakes or delays that often accompany manual work. Our device guarantees much better organization, repeatability, smoothness and economics of production. How was all this achieved?

How is an automatic production line from Magorex created?

The production line must perfectly match the needs and expectations of future users. Only then can we be sure that all processes will run quickly, efficiently and without any unexpected problems. When deciding on a specific device, many factors must be considered at the very beginning, such as the assortment and production volume, the conditions in the plant, the equipment owned, and even the requirements and qualifications of the staff.

We take all these aspects into account when we carry out individual orders. We ensure that the ready solution will be tailor-made, reliable, safe, and easy to use. Because we make all products ourselves in our plant, we are not afraid of evens the most non-standard projects. It also applies to the automatic production line. We can create it based on specific parameters and implement any modifications at the client’s request. During the first consultations, we jointly decide what mechanisms or additional elements to introduce to increase the ergonomics and efficiency of future activities. Then we move on to the rest of the construction details. At every stage, our consultants can propose options that will eliminate the risk of downtime and allow you to enjoy stable, high-quality results.